Technology at a glance

- The KEMREX Range Extender is perfectly suited for the rotary engine technology

- Battery Rightsizing: KEMREX is five times smaller and twice cheaper than an auxiliary battery

- E-Fuel as Alternative for 100 Procent CO₂-Neutrality

- Designed for Hydrogen fuel cell as a future option

Perfect application for rotary engines

The KEMREX electrical power generator unit is composed of a multi-fuel rotary engine, a generator, HV electronic components and various controllers. The unit generates HV DC power that is fed directly into the battery. The rotary engine is not mechanically attached to the drive wheels and is only used to generate electrical power. The engine always runs at a constant speed and the RPMs are set and maintained at the optimal performance point with the highest efficiency. This ensures minimal fuel consumption and an optimized exhaust emissions.

What is Battery Rightsizing?

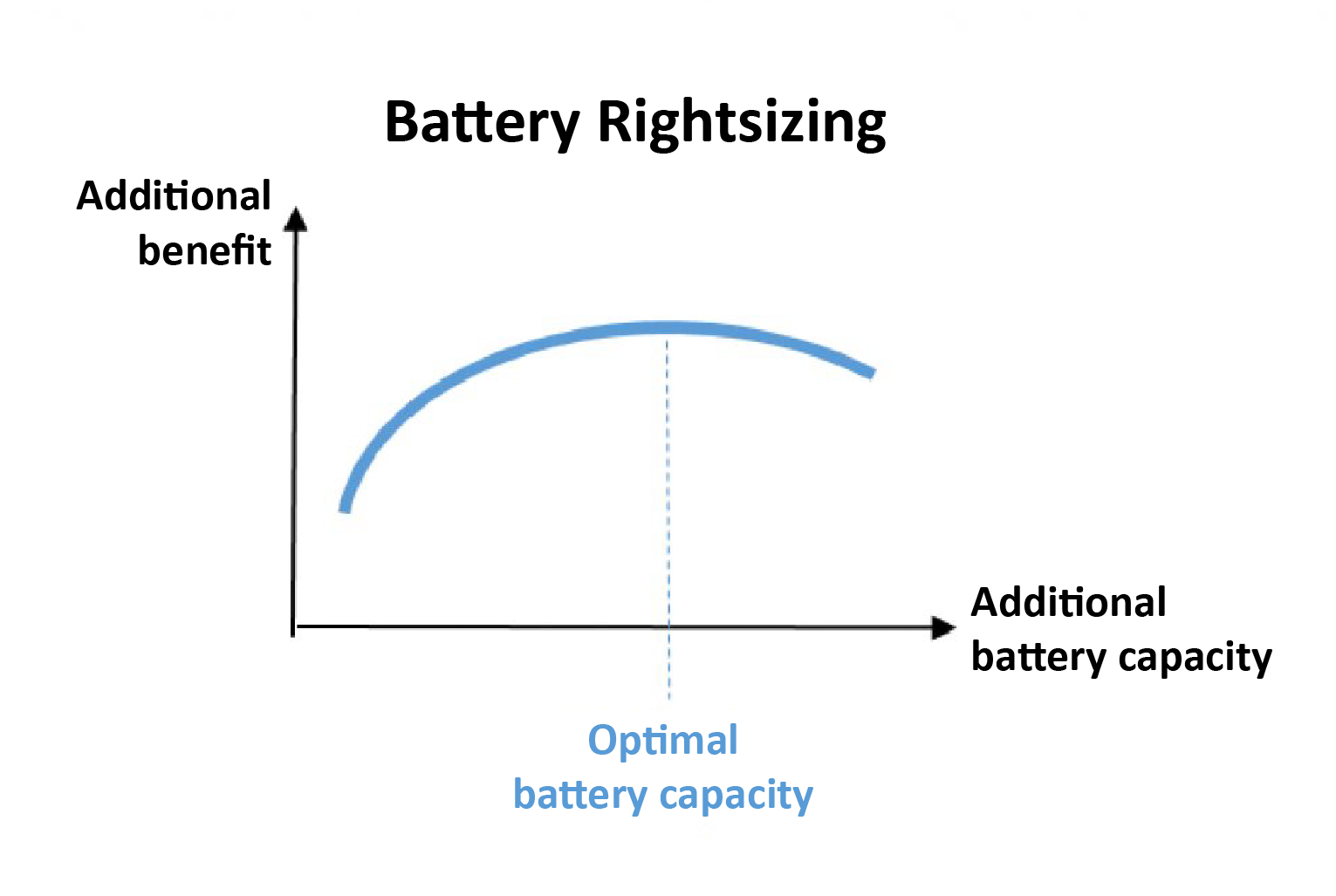

The KEMREX Range Extender is the key enabler for "Battery Rightsizing". Just installing a bigger and bigger battery to get more range is not always the best or even a viable answer. Established OEMs in the passenger car segment (for example: Mazda) have already moved in the direction of "Battery Rightsizing" and this principle will define the optimal battery size per vehicle for each generation of battery cell technology. According to the "Battery Rightsizing" principle there is an optimal battery capacity for each vehicle type based on the vehicles physical size and weight constraints. Installing a larger than optimal battery is actually counterproductive since the additional size and weight cancels out most or all of the theoretical extra range potential.

If the optimal battery capacity does not alone provide enough range for the customer application, then the vehicle must have an additional energy source onboard. For commercial vehicles, stationary charging time is lost deployment time and the battery electric vehicle must have a mobile power unit like KEMREX onboard in order to truly replace a comparable conventional diesel vehicle.

The optimal battery size for a 12 ton distribution logistic truck with the currently available battery cell technology is between 120 – 140 kWh. Unfortunately, the daily tour for a typical City logistics application requires almost twice that much energy. This is where the range extender offers the ideal solution.

Zero Emissions with KEMREX

The E-truck from Knapp e-Mobility has a 100% battery electric drive system and drives as a zero emission vehicle in regulated zones. When the combustion engine in the range extender is running on synthetic e-fuels, the entire vehicle is CO₂-neutral and the battery is charged “on-the-road” to achieve more range. Even if the customer chooses to run the KEMREX Range Extender on conventional Diesel fuel, the E-truck will reduce CO₂-emissions in comparison to a conventional Diesel truck by 80 und 90 Percent. Since the battery electric vehicle alone does not have enough range to cover the typical daily tour distance – it is not capable of replacing the Diesel truck at all and hence this “Option” saves no CO₂ at all.

Even if the battery cell technology improves from year to year - there are thousands of applications with tour distance requirements than can only be solved with the range extender. E-Trucks with KEMREX enable Customers to replace conventional Diesel trucks now – in real world applications, and with significant savings in CO₂-emissions.